Carrello

Like a copilot for your operations

Carrello gives your robots an additional set of eyes.

Carrello efficiently manages your material handling workflows and cart transportation tasks with speed and precision.

It monitors cart movement in real time to ensure supplies flow smoothly, teams stay stocked, and used materials are removed promptly.

By identifying carts ready for pickup, Carrello works seamlessly with your robot system to initiate efficient delivery and retrieval tasks and keep your operations running smoothly.

Streamline Every Department with Carrello’s Intelligent Automation

SUPPLY CHAIN

Material delivery

Ad-hoc delivery

Container return

LINEN

Clean linen restocking

Soiled linen cart pickup

Empty cart replenishment

TRASH

Full trash bin removal

Empty bin replenishment

NUTRITION

Meal cart delivery

Dirty tray cart return

The Carrello vision system transforms cart handling into a smart, automated workflow that keeps your teams stocked and your operations moving.

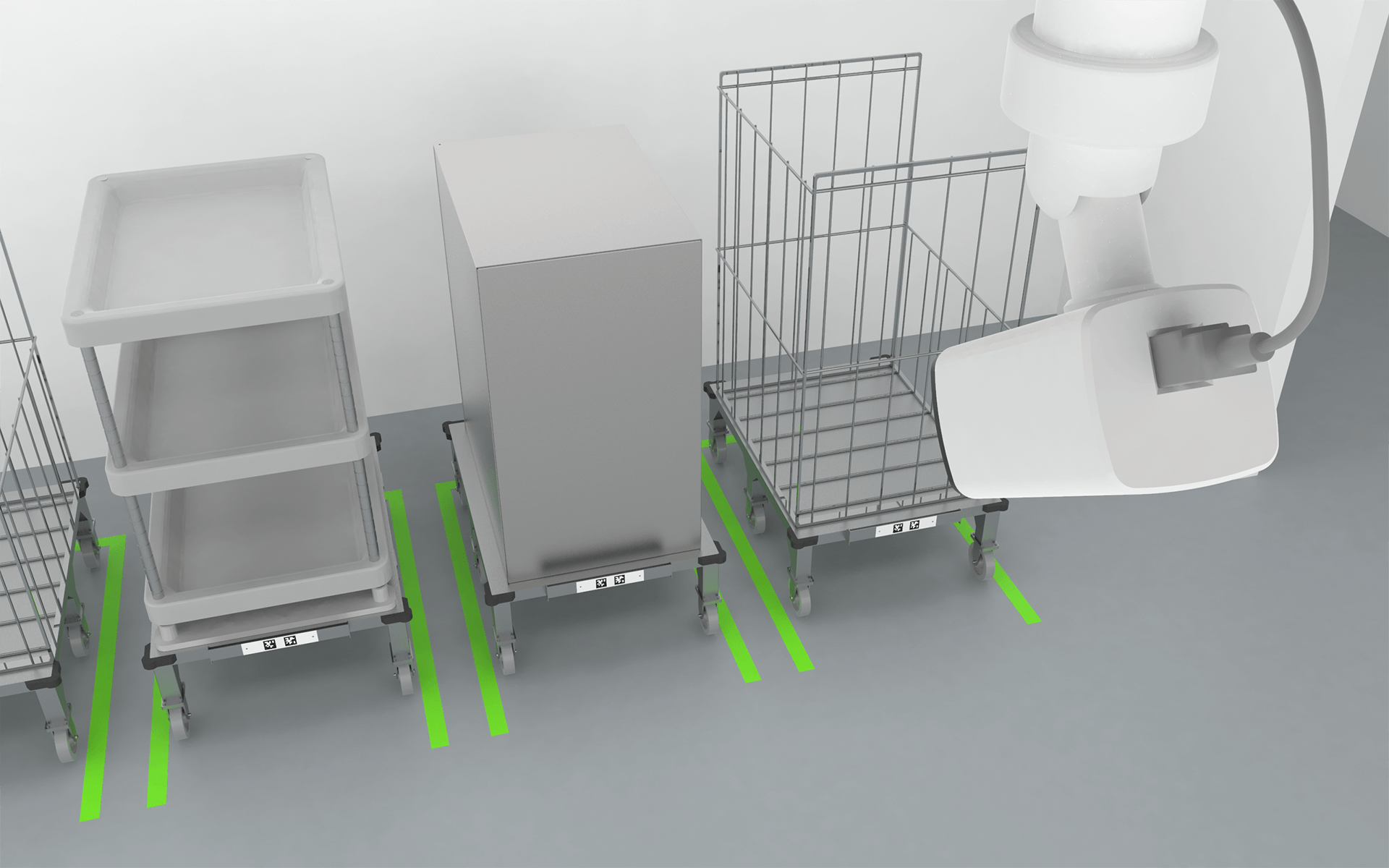

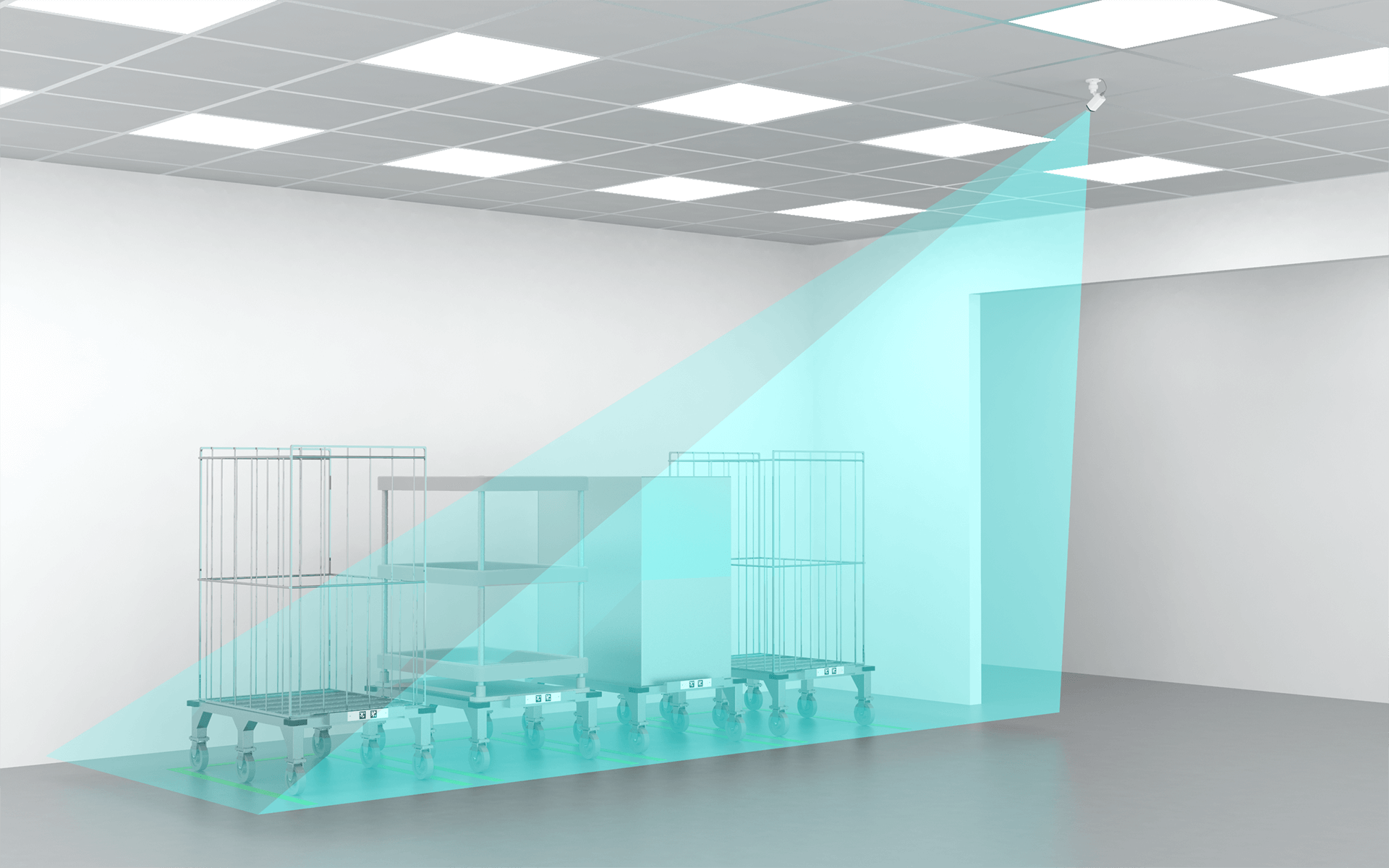

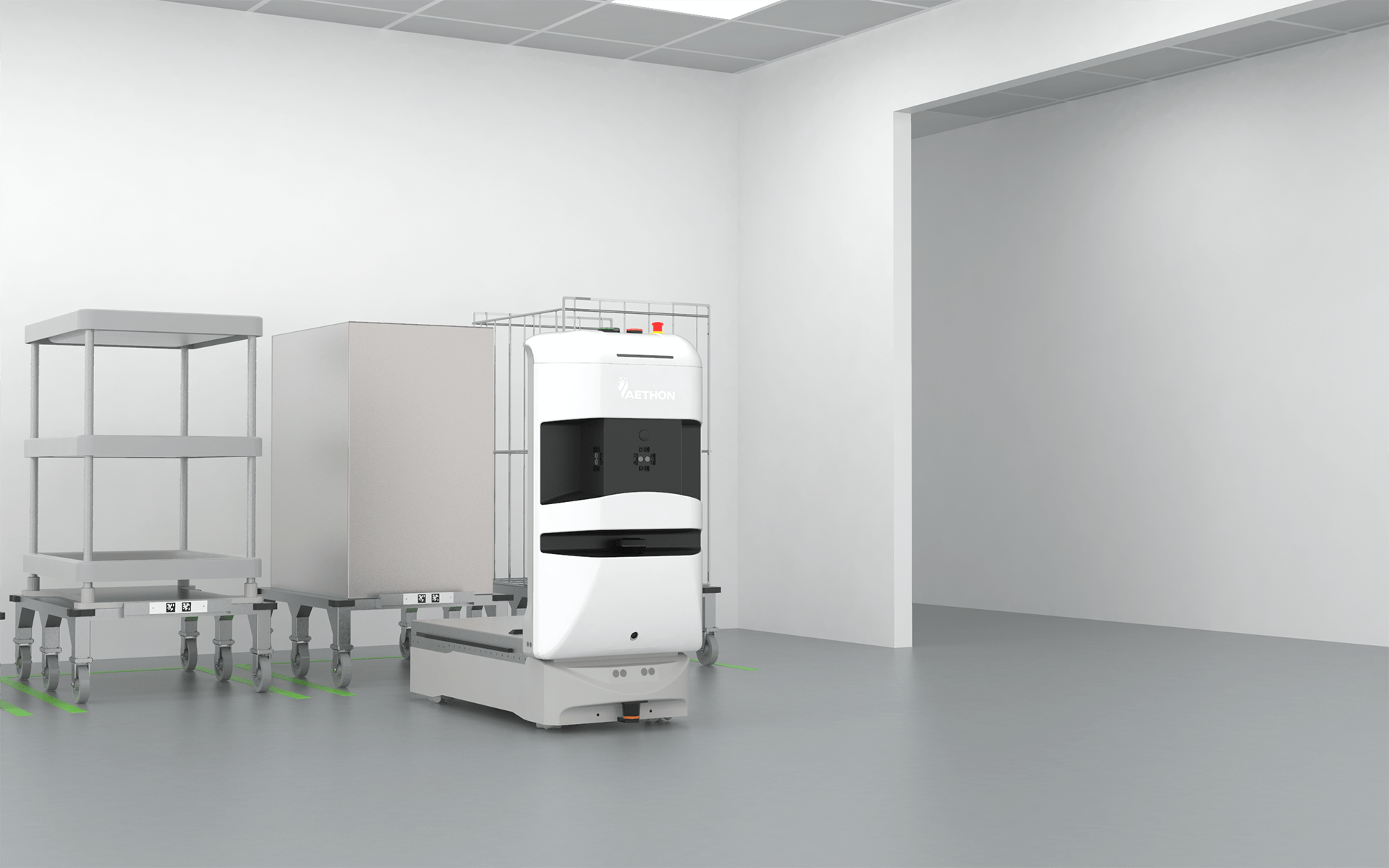

How Carrello works

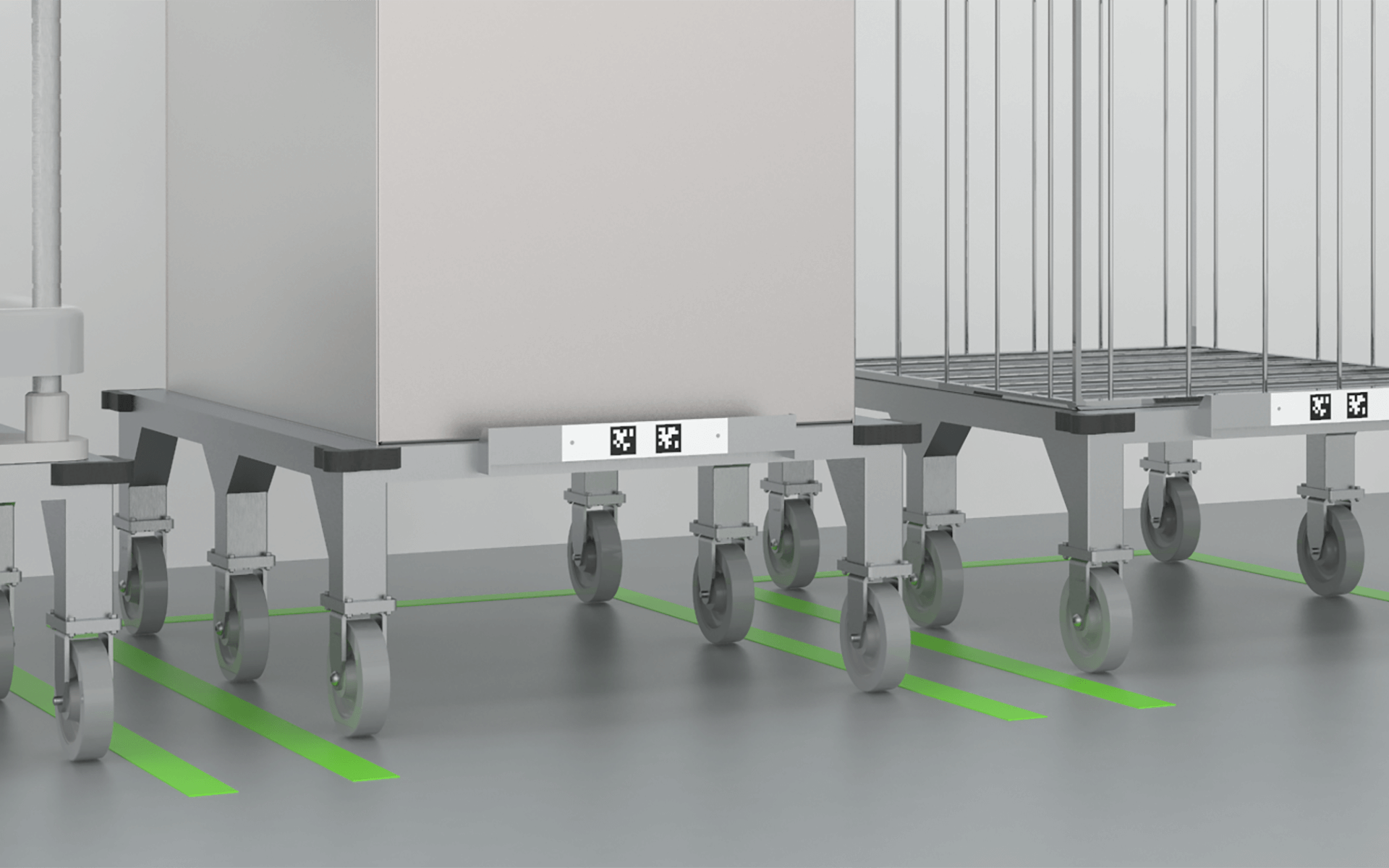

1. A compact industrial-grade camera monitors cart parking spaces and is easily mounted on a ceiling or wall. It’s powered by the visual processing unit, enabling seamless integration and reliable performance.

2. Multiple parking spaces are monitored simultaneously as the system looks for a cart to deliver or an empty space with ‘kan-ban’ rules for replenishment.

3. The visual processing unit analyzes the image, identifies the cart and its exact location, and sends only the essential reference data to Carrello.

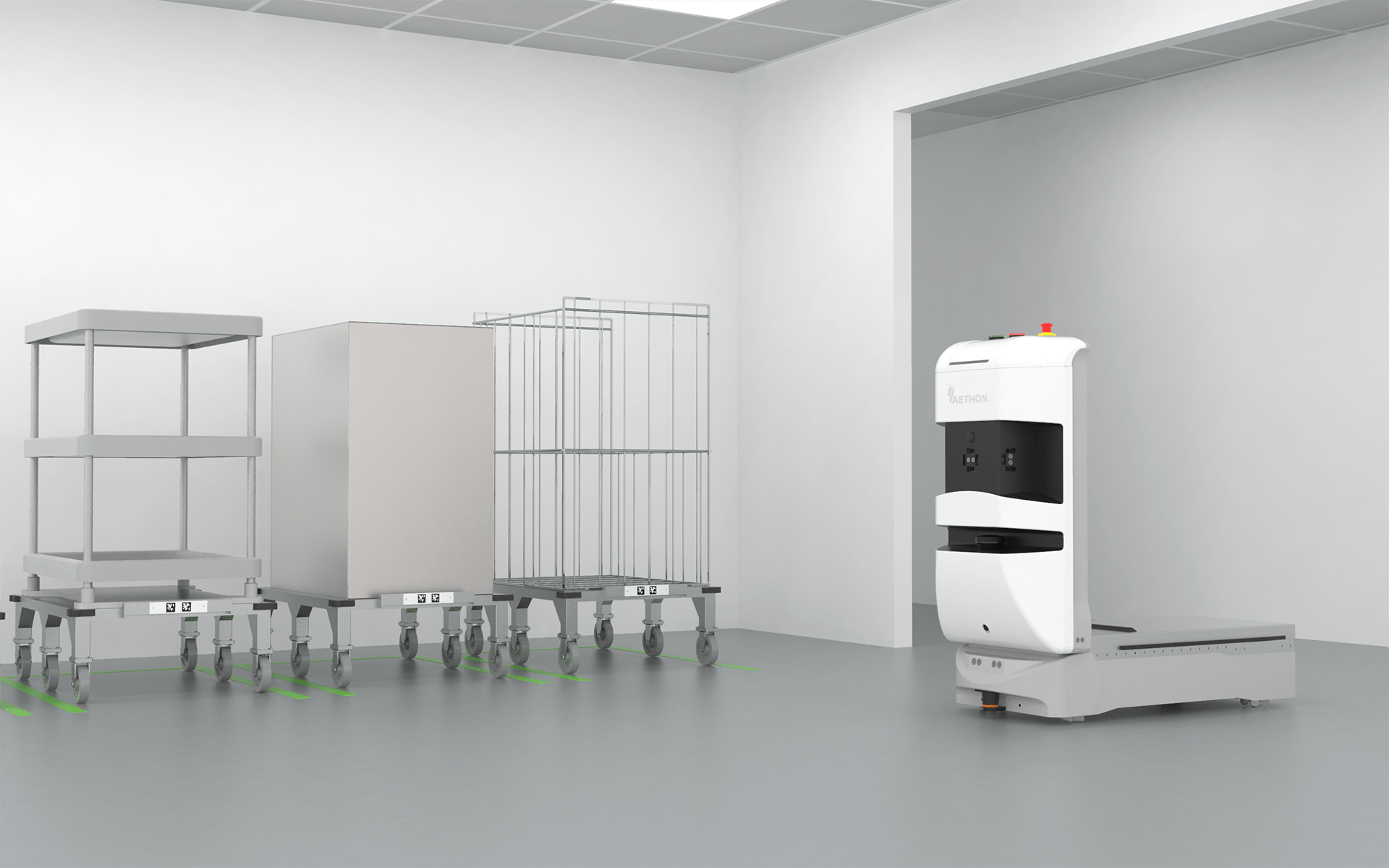

4. When the hospital’s workflow rules are triggered in Carrello, a robot is automatically dispatched to carry out the task.

4. The robot picks up the cart and begins its delivery route.

5. The robot delivers the cart to its assigned location and, on the same trip, may pick up another cart for return.

Carrello is Physical Artificial Intelligence In Action

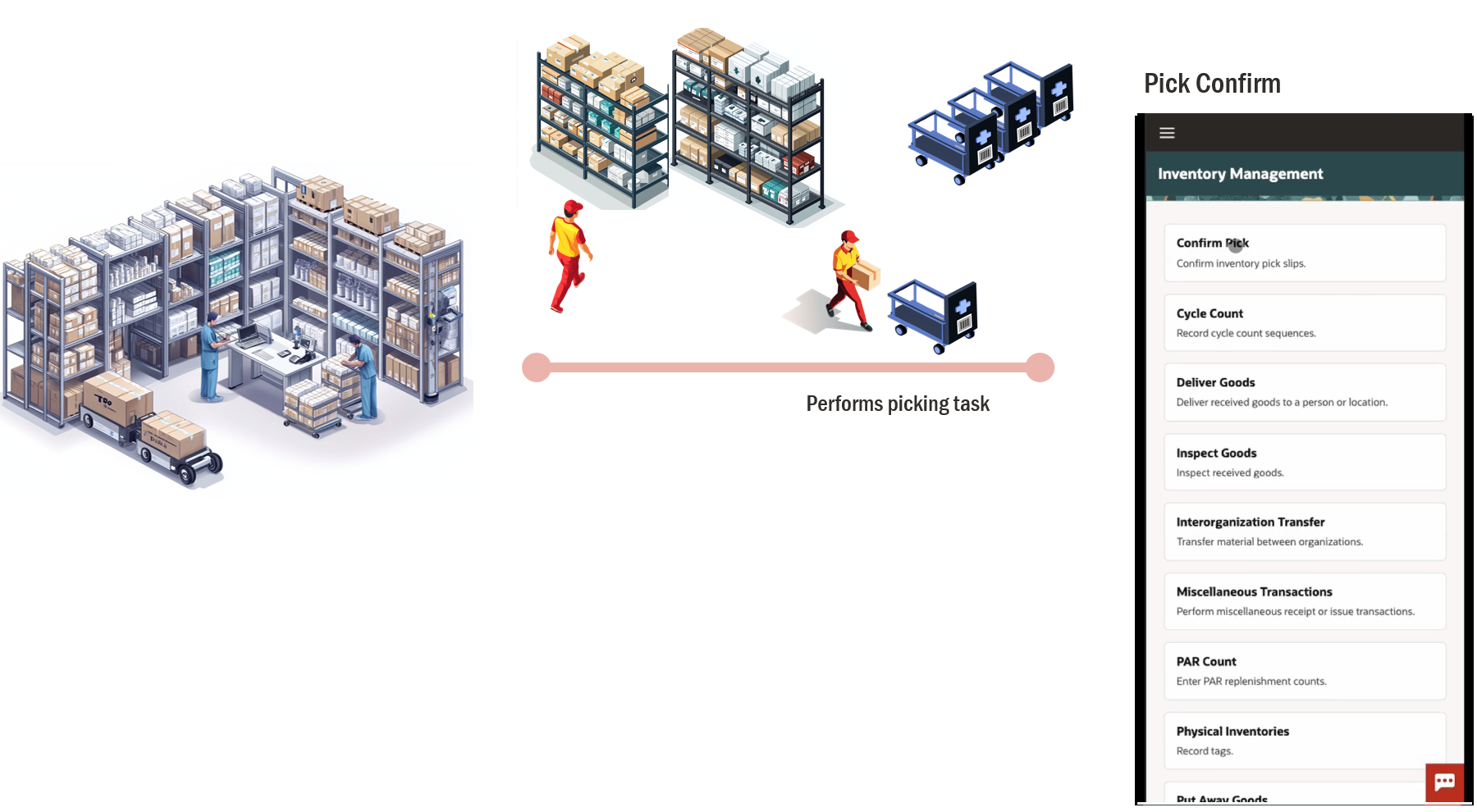

Out-of-the Box Integration with Oracle

In a first-of-its-kind integration, Aethon has partnered with Oracle to further automate supply chain processes in healthcare.

Carrello is now connected directly to the Advanced Inventory module within Oracle Fusion Cloud SCM, enabling real-time coordination between inventory and robotic delivery.

This integration streamlines the delivery workflow and completes the transaction process, improving efficiency, accuracy, and visibility across hospital systems.

How It Works

The process begins in Oracle Fusion SCM, where a warehouse team member starts the Confirm Pick workflow.

They select an order and scan a cart to transfer the inventory.

Once all items on the pick list are gathered, the team member marks the pick as complete and places the cart in the designated area for delivery.

From that point forward, Carrello and the robots take over—automating the delivery and ensuring everything moves efficiently.

1. Queries

Carrello detects the cart identifier and queries Oracle for the delivery location.

2. Picks Up

Robots are sent out to retrieve the carts.

3. Delivers

The robots deliver the cart to the designated transfer location provided by Oracle.

4. Confirms

After delivery, Carrello signals Oracle to complete the inventory transaction.

Robots in our family